Manufacturing Site Monitoring System 'REX Live'

Improving operational efficiency! Introducing a system that has continued to evolve through over 10 years of operational experience.

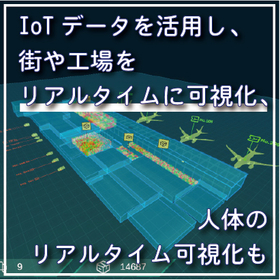

"REX Live" is a Manufacturing Execution System (MES) designed to visualize the manufacturing site and enhance on-site capabilities. It supports various manufacturing environments with a performance collection interface tailored to the characteristics of the manufacturing site. By collecting, aggregating, and providing quality, efficiency, and production information in real-time, it contributes to the improvement of QCD (Quality, Cost, Delivery). Additionally, through the practice of continuous improvement activities, it fosters personnel who can drive improvement initiatives. [Features] ■ Evolved through over 10 years of operational experience ■ Supports various manufacturing environments with a performance collection interface tailored to site characteristics ■ Provides assistance based on accumulated experience and know-how from system implementation to operation ■ Enables real-time understanding of production status and equipment operational status ■ Allows for constant monitoring of manufacturing site indicators and performance against targets, facilitating smooth daily management *For more details, please refer to the PDF document or feel free to contact us.

- Company:米沢工機

- Price:Other

![[Case Study] Visualization of Production Sites](https://image.mono.ipros.com/public/product/image/829/2000575150/IPROS12871026017551664274.png?w=280&h=280)